We place great importance on product quality. Even the most demanding customers find pleasure in our furniture.

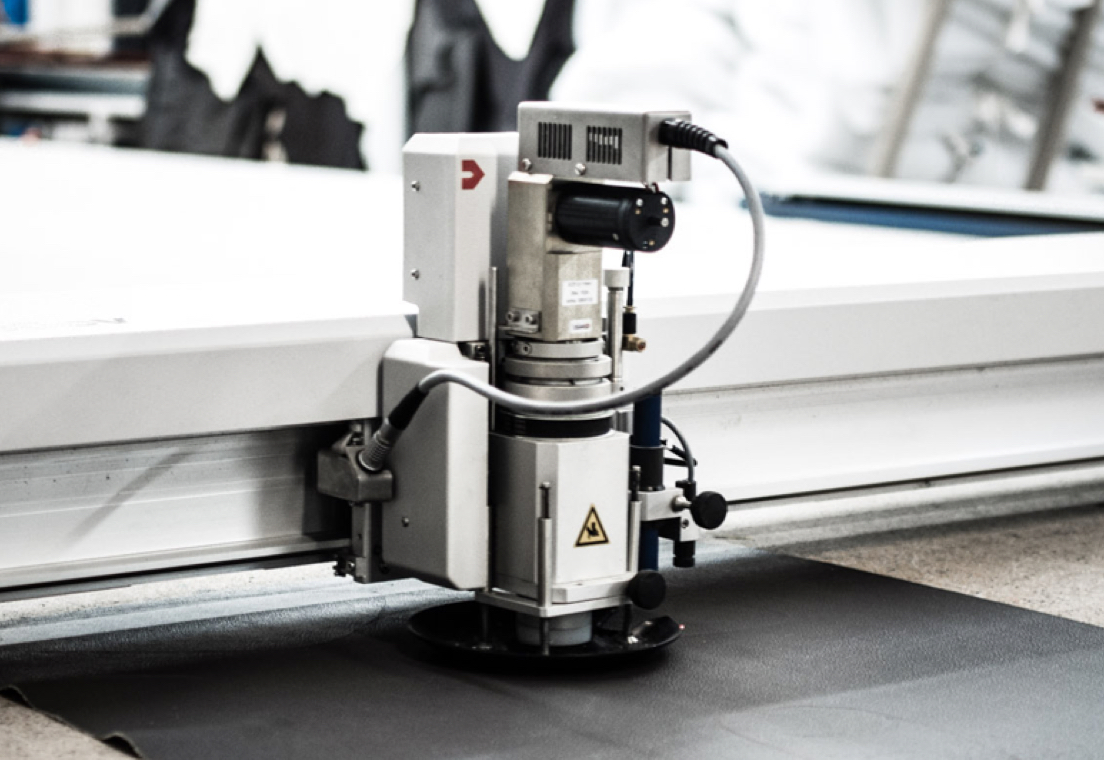

We only use up-to-date equipment and experienced employees when creating beautiful, comfortable and practical furniture solutions. We register every manufacturing stage so that in the event of a problem, we will be able to determine the exact reason and prevent the same mistake from reoccurring.

We are also able to successfully fill large orders, thereby allowing customer to be more flexible when organising campaigns.